A few years back, I was glad to be a part of a team that implemented a monitoring solution for a Gold production giant in Ghana to address some pertinent environmental concerns. The solution had to make continuous 24-hour measurement observations to the open pit mine walls, analyze and detect the slightest of movements which are then used to determine stability and predict wall failures in advance; preventing disasters, saving lives and protecting equipment. Being the first of its kind that we had undertaken in our capacity as partners of Leica Geosystems, it was a very rewarding and noteworthy but also challenging experience.

The Mine Operations

The mine was one of Newmont's operations in the Sub-Saharan region. The pit lies within the Sefwi Volcanic Belt, one of Ghana’s largest volcanic belts; an open-cast surface mine measuring approximately 2100 x 450 x 120 m. Traditionally, land surveyors had used manual total stations to measure distances and bearings from the mine to hundreds of fixed-prism targets installed in the walls of the open pit. At the time of writing there were about 300 prisms installed in the mine pit and more prisms added weekly, to cover all slopes in the pit walls. These readings were taken daily, usually multiple sets, then submitted to the geotechnical engineers to conduct their analyses. Geotechnical engineers will usually receive thousands of x,y,z coordinate pairs or distance-bearing polar readings. This manual way of performing monitoring changed after the new system was implemented.

Overview of the system

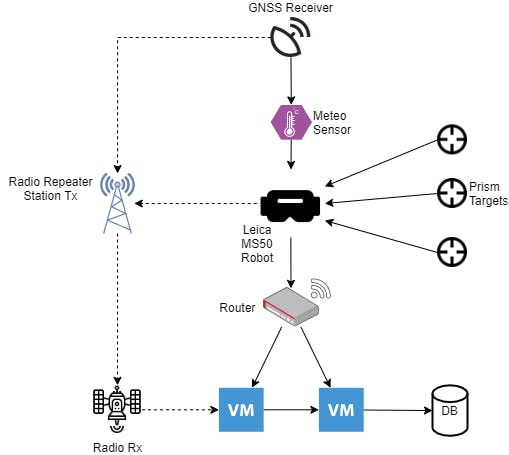

The system installed consists of an optical robot (Leica NOVA MS60 MultiStation) - which automatically learns and makes measurements to the carefully distributed targets, DTM meteo sensor and a Netmodule Industrial Router all getting power from a 12V Solar Panel Power supply. Leica GeoMos Monitor and Leica GeoMos Analyser software installed in VMs, for analyses and data aggregation. The GNSS receiver installed at the station receives differential GPS observations to check relative movements at the monitoring base. The Netmodule Industrial Router handles communication and serves as a WLAN client and a conduit for data flow between the MS60, GeoMOS and the Meteo Sensor. Geomos connects to the MS60 via a Wi-Fi network, collects data from the sensors and stores them in a SQL database. For high availability, there is also a secondary radio network that the system automatically fails over to when anything goes wrong with the primary network.

The DTM Meteo Sensor is installed close to the monitoring station to measure atmospheric variations in temperature and pressure. These data are used to correct the measured slope distances by the MS60 sensor.

The Ms60 was chosen over other monitoring sensors because it had the added capability to make reflectorless 3D scans and had made a reputation as the world’s first self-learning MultiStation, automatically and continuously adapting to any environment, despite the challenges. Data from the MS60 sensor is a combination of scans of sections of the mine wall as well as measurements to installed prisms in the mine wall. This data is analyzed and organized by GeoMOS and stored in the database.

With this monitoring system installed, it is possible for geotechnical engineers to perform 24-hour continuous slope stability analyses. The data from the system makes it possible for slope failures to be predicted in advance. What are your thoughts?

UPDATE 2017: A more detailed account of this project appeared in Leica Geosystem's magazine Reporter 76.